Anodize

Anodizing is an electrochemical process where a hard clear layer of oxide is created in the surface of the metal. The oxide structure that is created is composed entirely of aluminum and completely integrated. Making the metal more durable and resistant to corrosion. The hard oxide is extremely porous and therefore color can be added to the surface layer. Depending on the specifications, the thickness of the layer can be manipulated to the client's needs.

Color

At ANODIZE we are capable of anodizing aluminum in a variety of colors. The world is your palate. Our everyday colors are Natural, Black and Gold. We can, upon request of a project, we can develop any other color specifications. Our current lineup of colors for small projects are Red, Blue, Green, Violet, Turquoise.

Die Cast Aluminum

Anodizing Die Cast Aluminum is very tricky. Fortunately, our experience has gives us the opportunity to optimize our solution tanks to give the best results. This type of aluminum is usually used for fluidity and ease of casting, not always designed for surface appearance or properties. The primary reason for anodizing die cast is for corrosion resistance and durability.

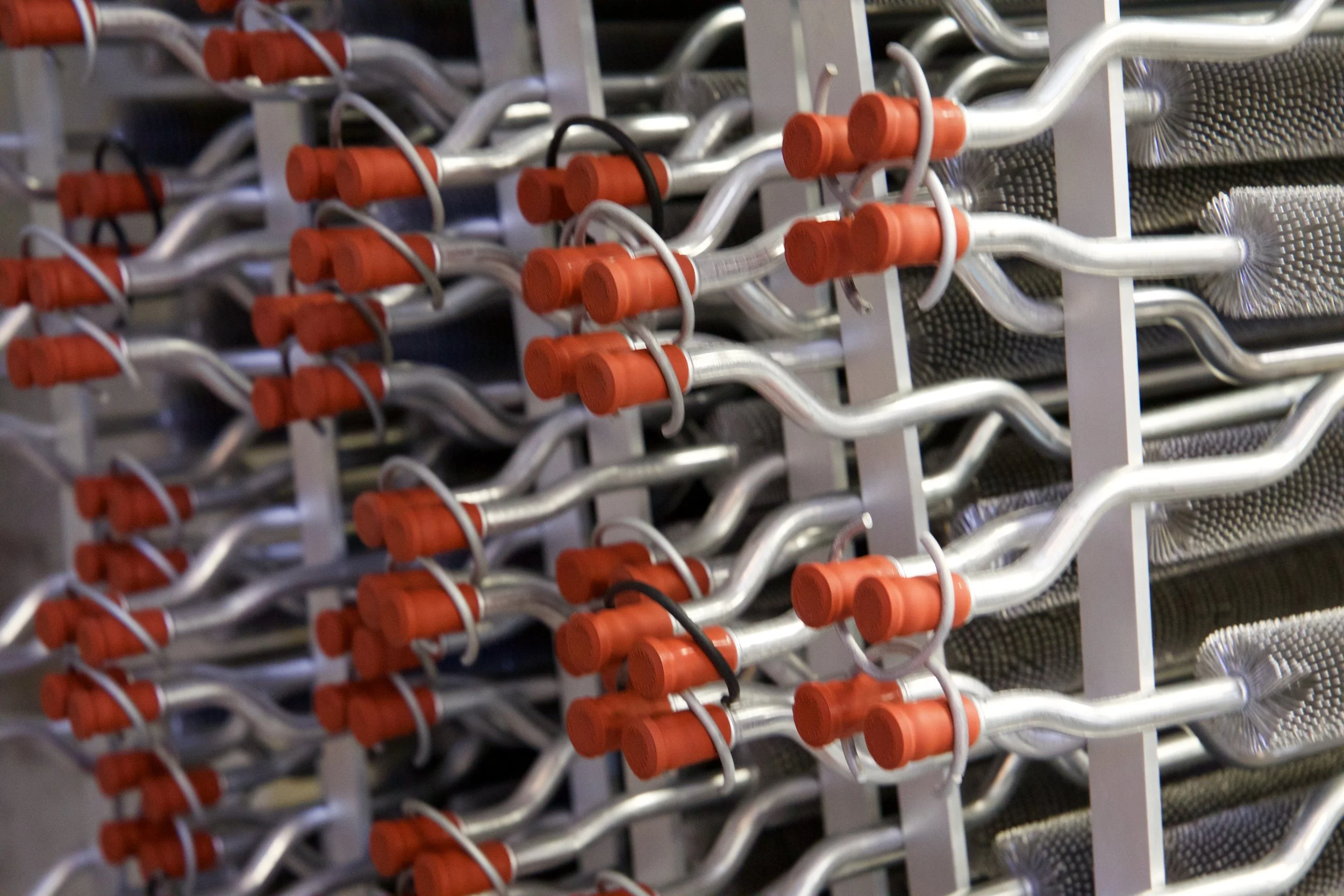

Masking

Masking prevents an area form being anodized. This is commonly done when dimensional issues may appear or when there is a need of electric conductivity. It may be a crucial step in the process to ensure that the part will work in accordance to their engineering specification. Depending on the requirements, masking an area can be achieved with a variety of technics. Each project demands its specifications.